Views: 104 Author: Site Editor Publish Time: 2021-11-27 Origin: Site

Overview: Automatic flow control mechanisms known as solenoid valves are widely used in a variety of industrial applications. These valves are quick-acting, have a low power requirement, provide reliable fluid service, and have a compact design. How do these valves attain their distinctive performance qualities? Their designs and the electromagnetic operation of the valve's parts hold the key to the solution.

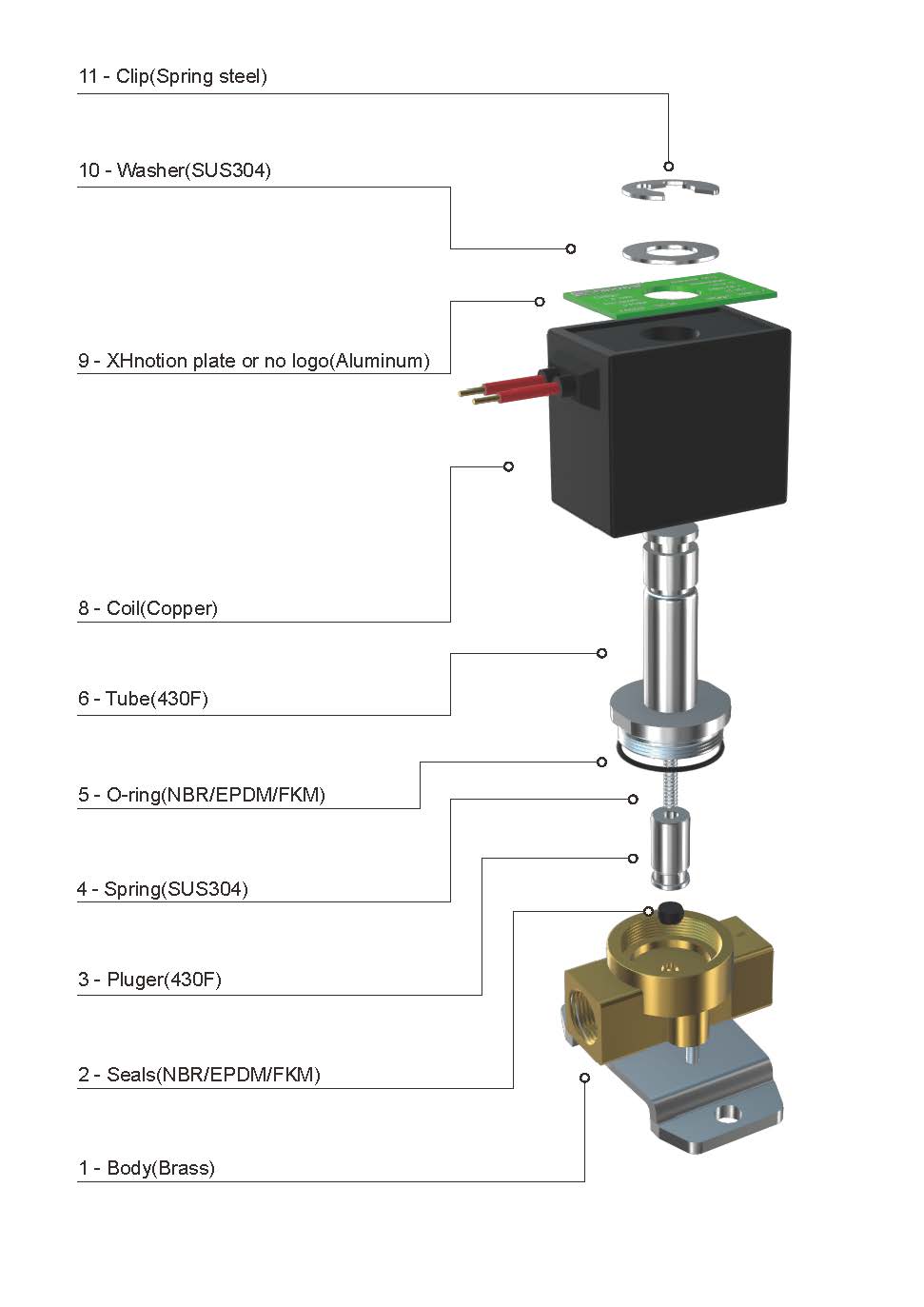

Introduction: A solenoid and a valve body with orifices make up a solenoid valve. An inductive coil encircles a ferromagnetic core, also known as the plunger, in a solenoid. By sending electric signals via the coil, you can energize it and produce a magnetic field. The plunger is drawn to the magnetic field and moves linearly inside the valve body. The plunger is moved to a secondary position concerning the orifice locations because the magnetic force generated by activating the solenoid is strong enough to overcome both inertia and the mechanical force of an opposing spring. The numerous valve orifices are sealed or opened as a result of movement.

Application: Solenoid valves can open or close the flow of fluids, control flow rates, distribute or mix service fluids in a pipe system, and have a variety of circuit configurations. Examples of typical application areas include automated process controls, on/off fluid service, hydraulic and pneumatic loops, water supply, fuel supply, air conditioning systems, and wastewater treatment.

These valves are reliant on the electromagnetic field to function. They can work without the use of an additional actuator or external pressure. Even when there is no pressure difference between the valves, direct-acting solenoid valves can open or close. The electromagnetic field produced by powering the solenoid will cause the plunger to move.

A standard direct-acting solenoid valve has either a typically open or normally closed configuration. A spring is used in a generally available solenoid setup to retain the seal away from the orifice's seat, maintaining the flow path's openness as long as the coils are de-energized. A seal is pushed toward the center by an electromagnetic force produced when electrical power is applied, stopping flow in the desired direction. When a circuit is generally closed, the opposite is true. When the solenoid coil is activated, the seal is lifted from the orifice seat, allowing fluid to flow via the flow path.

Since the actuation mechanism is located inside the valve body, direct-acting valves have a compact design. They work well in applications with moderately low flow rates. The diameters of the orifices and the magnetic force determine the flow rates and permissible pressure limits for fluids traveling through direct-acting solenoid valves.

A direct-acting solenoid valve can choose the normally open or closed configuration. These are referred to as "latching solenoid valve" or "bi-stable solenoid valve"

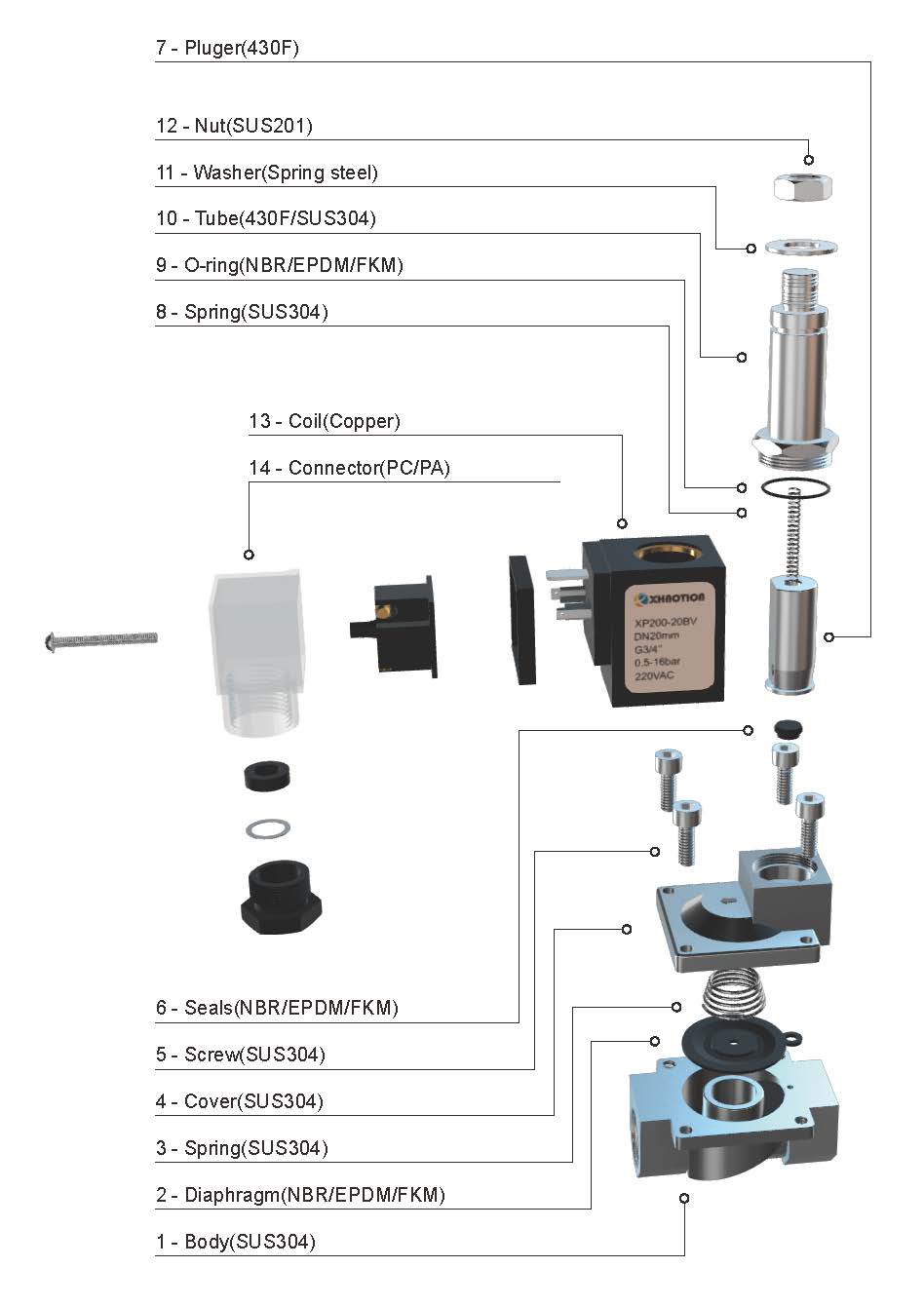

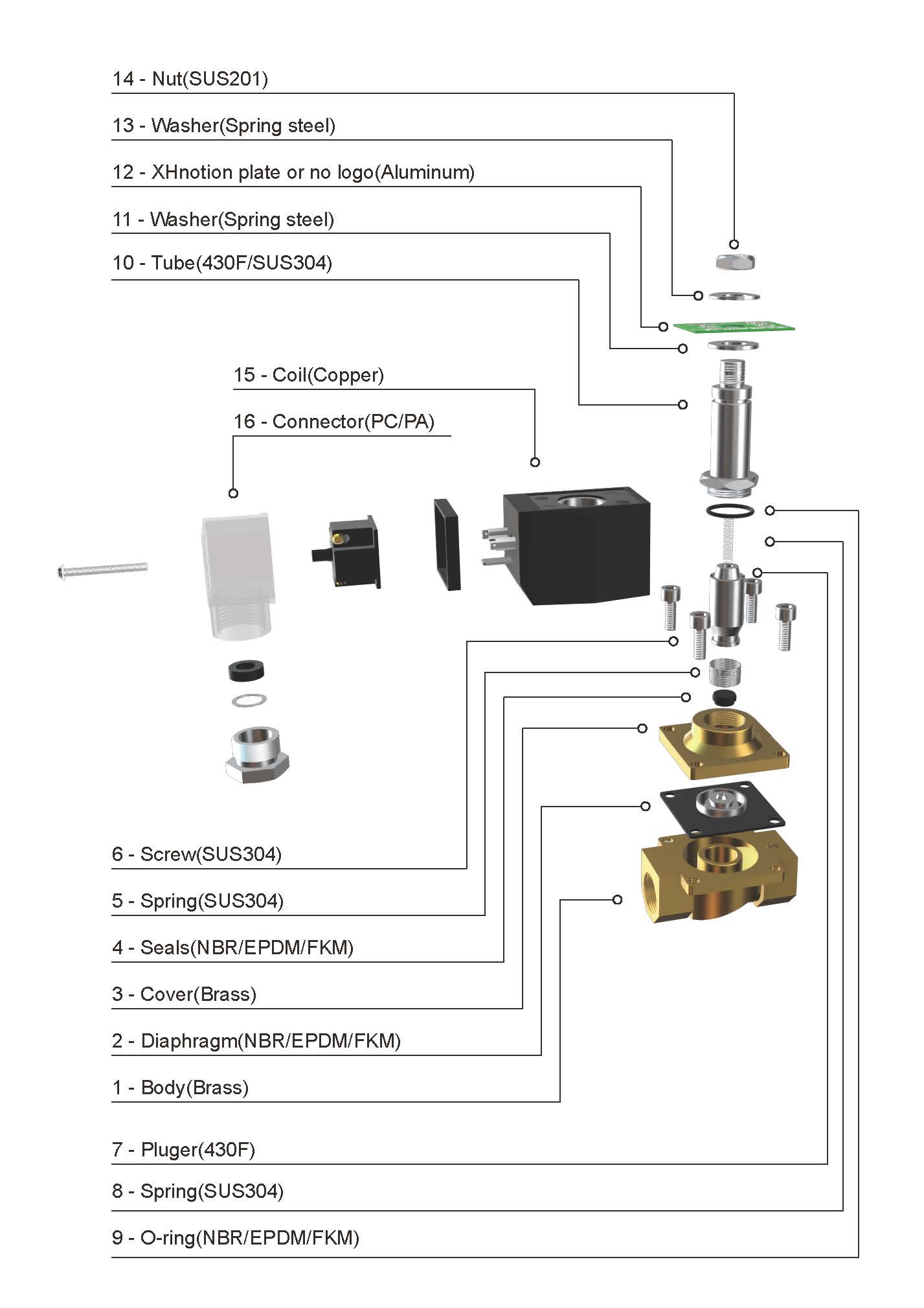

The service fluid's pressure is necessary for these valves to operate in some capacity. They are frequently used in fluid applications with high operating pressures and flow rates. These valve solenoids produce strong enough forces to regulate the opening and closing of pilot orifices. The pilot orifice allows or expels fluid into or out of the top cavity as it opens or closes, keeping the valve diaphragms in their proper locations.

When a pilot operates a solenoid, the service medium passes through the pilot orifice and exerts pressure on the top side of the diaphragm, keeping it closed. The diaphragms in the valves are held against the main valve orifice by mechanical springs, obstructing flow channels. No liquid passes through the valve. The service fluids are released from the top compartment and into the main pressure line when the solenoid is activated. It causes a pressure difference between the diaphragm's lower and upper sides. The primary valve opens when the differential pressure pushes past the diaphragm's and the springs' resistance.

The pilot valve typically has a narrower opening than the main valve. With these orientations, little pilot valves can operate huge valves with minimal energy. These valves work less quickly than their direct-acting equivalents. They are appropriate for industrial processes requiring high flow rates, steam facilities, and high-pressure hydraulic systems.

The characteristics of direct and indirect valves are combined in semi-direct-acting solenoid valves. Because of this, they can operate at zero bar while still having a high flow rate. They have a moveable membrane with tiny openings and pressure chambers on both sides and resemble indirect valves. The solenoid plunger's direct connection to the membrane marks a distinction.

The membrane is directly lifted when the plunger is raised, opening the valve. The plunger simultaneously causes a second hole in the membrane, which has a slightly bigger diameter than the first orifice, to open. As a result, there is a decrease in pressure in the chamber above the membrane. As a result, the membrane is raised by both the pressure difference and the plunger.

Assisted-lift solenoid valves are another name for semi-direct operated valves. Semi-direct-operated valves frequently feature coils with greater strength than indirect-operated valves. This combination produces a valve that can manage reasonably high flow rates and function at zero bar.

Beyond the typical on/off fluid service in a piping system, three-way solenoid valves offer additional flow control. They can be used to combine fluids from two different sources or to divert fluids from one inlet to two various destinations. These valves can be oriented with two outlets and one inlet port or two outlets and one inlet port. Depending on how configured, these valves can provide dependable service for mixing or directing fluids.

The 3-way solenoid valve has two outputs and one inlet port, which is used to change the direction of fluid flow. In the initial configuration, fluid will enter through the input orifice and exit through one outlet while the other stays closed. The flow is switched from the initial closed outlet's primary path to the secondary way by energizing the solenoid coils. One of the inlets is initially open, while the other is first closed in mixing applications. The fluid enters through the open inlet, travels through the valve, and exits through the shared outlet. The plunger advances to a position that blocks the initially open orifice after igniting the solenoid coil, and the secondary orifice opens to permit the flow of fluids.

To enable automated valve operations in various applications, most solenoid valves may be predictably fixed to actuators. Standard solenoid valves with specific mounting patterns and installation styles are necessary for many applications. The name of these valves is NAMUR mount valves.

Pneumatic actuators with a standardized mounting pattern can handle specific solenoid installation configurations. The valves can offer flow pathways that are 3-way, 4-way, or even 5-way. These valve solenoids are activated, which causes plungers to move into various positions and open or close the orifices as necessary. To ensure the accuracy of pneumatic applications, NAMUR mount valves should be chosen that suit the pipeline's flow requirements and have an appropriate reaction time.

More details, please refer to https://www.xpneumatic.com/a-coverall-guide-to-choose-a-right-solenoid-valve/

Email: sales@xpneumatic.com